top of page

Business Challenges

Supply Chain Network Design

Supply chain network design focuses on choosing optimal facility locations, defining flows, and balancing costs to ensure efficiency and resilience.

It is a continuous process supported by advanced software tools, enabling better forecasting, optimization, and decision-making than spreadsheets.

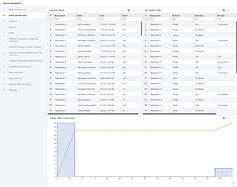

anyLogistix combines optimization and simulation to design and improve supply chain networks end-to-end.

It supports Greenfield analysis for initial facility placement and network optimization to balance supply, demand, and costs with detailed data-driven insights.

Inventory Optimization and Planning Software Tool

anyLogistix (ALX) enables inventory optimization through simulation-based digital twins, helping cut costs while maintaining customer service levels.

It supports both single-echelon and multi-echelon optimization, preventing issues like the bullwhip effect by aligning policies across the whole supply chain.

Simulation allows handling randomness, modeling detailed processes, and testing “what-if” scenarios such as supplier failures or demand surges.

With ALX, companies can estimate safety stock, analyze inventory dynamics, and create efficient, resilient inventory strategies.

Supply Chain Risk Management Software

anyLogistix (ALX) helps mitigate supply chain risks by using simulation-based digital twins to model operations, uncertainties, and disruptions.

It supports both operational risks (e.g., demand fluctuations, delays, stock-outs, equipment failures) and disruptive risks (e.g., supplier bankruptcy, disasters, political crises).

Simulation enables testing “what-if” scenarios, quantifying risks, and developing contingency plans for resilience.

With ALX, companies can minimize losses, improve responsiveness, and design lean, resilient supply chains.

Sourcing Planning and Optimization Software

anyLogistix (ALX) sourcing optimization helps companies make better supplier and internal sourcing decisions by simulating real supply chain dynamics.

It evaluates suppliers by cost, reliability, lead times, discounts, and risk factors, while also testing contingency scenarios like bankruptcy or demand surges.

ALX supports internal policies such as site expansion, warehouse placement, and transportation choices, optimizing cost and service balance.

With its simulation-based approach, ALX uncovers cause-and-effect links, handles uncertainty, and provides superior decision support compared to traditional tools.

Supply Chain Master Planning

Supply chain master planning synchronizes production, storage, and transport with demand to improve efficiency, cut costs, and avoid stock-outs.

It is a mid-term process (weekly/monthly) guided by forecasts, seasonal demand, and KPIs to align all supply chain elements.

Without it, inefficiencies rise, requiring larger buffers and leading to higher costs.

Using anyLogistix (ALX), companies can create a digital twin to optimize and simulate coordinated production, transport, and storage plans at minimum cost.

Cash to Serve

Knowing cash flows is vital to identify profitable products and customers, but complexity in multi-echelon supply chains makes this analysis challenging.

anyLogistix (ALX) uses simulation modeling and digital twins to provide clear visibility of financial dynamics across the supply chain.

Its cash-to-serve analysis tracks cash on hand, loans, interest, payables, receivables, and payment terms to guide decisions.

By simulating policies and scenarios, ALX helps improve service levels, cut costs, and optimize margins with robust financial strategies.

bottom of page